Industrial Solutions

From its inception in 1958, Pioneer has been a leader in construction chemicals, marine, automotive & motorcycle, and industrial protective coatings market in the Philippines. Our adhesives and sealant products have become household brands and most sought by consumers. Our construction and industrial range of products has created loyalty among both craftsmen and professionals.

Pioneer Pro Industrial was established to concentrate its efforts in the specialized in industrial industry of chemical compounds, waterproofing, exterior wall systems, flooring, coatings, sealants and insulation.

DESCRIPTION:

Pioneer Pro Backing Compound is a two-part high solids epoxy compound, fast setting, non-shrinking with high volumetric stability, high compressive and impact strength designed for backing of wear metals in gyratory, primary and large cone crushers, grinding mills, ball mills, rod mills, pulverizers and other machineries.

HIGHLIGHTS:

1.Fast setting, Non-shrinking

2.High volumetric stability

3.High compressive and impact strength

4.Low exothermic reaction, Non-metallic compound

5.Needs no melting or special equipment

6.High solids content – Solvent free

7.Non-flammable, Non-hazardous to health

8.Easy, economical and safe to use

HIGHLIGHTS:

1.Fast setting, Non-shrinking

2.High volumetric stability

3.High compressive and impact strength

4.Low exothermic reaction, Non-metallic compound

5.Needs no melting or special equipment

6.High solids content – Solvent free

7.Non-flammable, Non-hazardous to health

8.Easy, economical and safe to use

PURPOSE:

- It serves a backing and reinforcing layer between machine parts and supporting cone and inner jacket in cone crushers.

- For backing wear metals in rod, ball, pebble and autogenous mills; cone and gyratory crushers.

- For filling of cavities between upper part of crusher and outer jacket. For gap filling between manganese steel liners and body of cone crushers and mantle.

- It serves as a damper when subjected to high impact and shock bearing loads.

CERTIFICATES:

- ASTM D695: Standard Test Method for Compressive Properties of Rigid Plastics

- ASTM D4541: Standard Test Method for Pull-off Strength of Coatings using Portable Adhesion tester

Pioneer Pro Wearing Compound

DESCRIPTION:

Pioneer Pro Wearing Compound Epoxy High Abrasion Resistant Ceramic Bead-filled epoxy is a two-part epoxy compound designed to rebuild and repair interfacing metal surfaces and high wear areas of processing equipment. It has outstanding resistance to hard sliding abrasion and corrosion, protecting metal from bi-metallic corrosion.

HIGHLIGHTS:

1.Non-Metallic-easy, economical and safe to use

2.Rebuilds and protects interfacing worn metal surfaces fast-reduces downtime.

3.Extends wear life-resists sliding abrasive wear

4.Protects metal from bi-metallic corrosion

5.No-slump formula – won’t sag or shrink.

6.Improves bottom line:

- Repairs are done at approximately 40% of replacement cost.

- Increase life or Pioneer Pro Wearing Compound Epoxy on protected processing and material handling equipment, lasting up to 10 times longer than non-ceramic linings.

PURPOSE:

- Pump liners and impellers, Pump casing

- Pipes and pipe bends, Chute linings

- Fan blades and housings

- Cyclone and separator bodies

- Transport elbows and transitions

- Dust collectors and exhausters

- Transition points, Hoppers, Scrubber

CERTIFICATES:

- ASTM D638: Standard Test Method for Tensile Properties of Plastics

- ASTM D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- ASTM D695: Standard Test Method for Compressive Properties of Rigid Plastics

- ASTM D4541: Standard Test Method for Pull-off Strength of Coatings using Portable Adhesion tester

- ASTM D4060: Standard Test Method for Abrasion Resistance of Organic Coatings by Taber Abraser (adapted method)

Pioneer Pro Special Formulation

DESCRIPTION:

Pioneer Pro Epoxy Grout is a two-part 100% solids modified epoxy compound with Silica sand. It is the best product for grouting applications and serves as an excellent protective barrier for harsh applications. It is impervious to chemicals and solvents and can withstand high torque loading.

HIGHLIGHTS:

1. 100% reactive

2. Provides superior bond

3. Moisture insensitive

4. May be applied to dry or damp surfaces

5. Curing time adapted to work schedule, No added waiting time

6. VOC compliant

7.High compressive strength

APPLICATIONS:

For splicing and casting applications

For securing anchor bolts, rebar and dowels in concrete

COMPLIANCE:

- Volatile Organic Content (VOC), g/L

- Component A: Not detected

- Component B: 33.96

- Limits: Multi-purpose construction adhesives – 70g/L

DESCRIPTION:

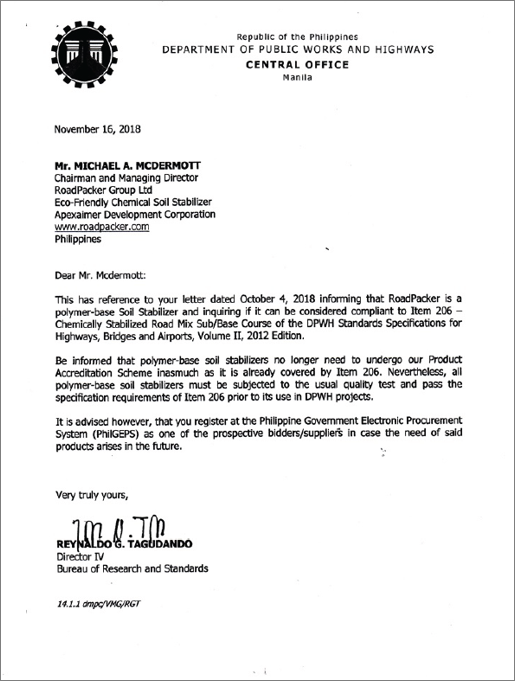

Pioneer Pro Road Packer is a polymer-based ionic soil stabilizer in liquid form. It has been at the forefront of developing unique ground stabilization road construction methods and is an effective in terms of level of compaction, water repellent performance, deployment time and, and overall cost. It is cost-efficient, you save up to 40% versus conventional road construction, and you won’t be needing any major maintenance within five years.

HIGHLIGHTS:

COST-EFFICIENT – Save up to 40% vs conventional road construction

ENVIRONMENTALLY SAFE – Non-toxic and Eco-friendly

FAST APPLY, HASSLE-FREE – Lesser usage of equipment, no special skills needed

HIGH COMPACTION RATE – Binding strength due to change in molecular structure of soil

NO MAJOR MAINTENANCE – Allow to reach its useful and service life, No frequent road repair

APPLICATIONS:

- Mining access roads

- Land development road for subdivisions and other constructions

- Farm-to-market roads

- Access roads to resorts and establishments

- Barangay roads and other road projects

COMPARISON:

Water Resistant – It becomes harder with traffic due to increased compaction

Eliminates wash boarding

Dramatic reduction in dust

Resistant to swelling and shrinkage

Fast and Easy to apply requiring no specialized equipment

Green, eco-friendly – Non-toxic, non-leaching

It has electro-magnetic that bind the particles of soil together to remain permanently in the soil

Water and traffic – dirt roads’ worst enemies

Wash boarding, transverse ripples

Dust causes poor visibility – road hazard

Prone to swelling and shrinkage

Lasts only 4-6 years thus, requiring costly regrading works

Costly maintenance – Requires grading every 1-2 months

Magnesium Chloride, often used as dust suppressant is harmful to plant and animal lives

Base course is prone to pulverize within 4-6 years

CERTIFICATIONS:

Compliant to DPWH Standards Specification for Highways, Bridges and Airports

DESCRIPTION:

PioneerPro GreatWall is an Expanded Polystyrene Insulation Board (EIPS) is affixed to the substrate and creates a layer of continuous insulation.

HIGHLIGHTS:

Features:

Expanded Polystyrene Insulation

No off gassing

Continuous Insulation (CI)

Easily cut

Benefits:

Energy Efficiency

R-Value remains constant

Meets energy codes

Create multiple and diverse architectural styles

DESCRIPTION:

Building with SIPS will save you time, money and labor.

HIGHLIGHTS:

Superior in shear resistance, flexural strength and uplift resistance. Resist structural damage caused by typhoons and earthquakes. Ultimate flexural load is 2,100 lbs.

Reduces temperature gradient and distributes cooling more evenly, making for a more comfortable (and controllable) indoor environment as well as ambient noise. It has superior indoor air quality that protects against outside pollutants and have a cooling feature during summer.

Unique properties of SIPS allow for almost all building shapes and options that architects/designers are looking for and ideal for both commercial and residential applications.

Reduces energy consumption (energy efficient), thereby reducing carbon dioxide and pollutants. Minimal construction waste.

Fast and easy to install resulting to faster turn over of projects.